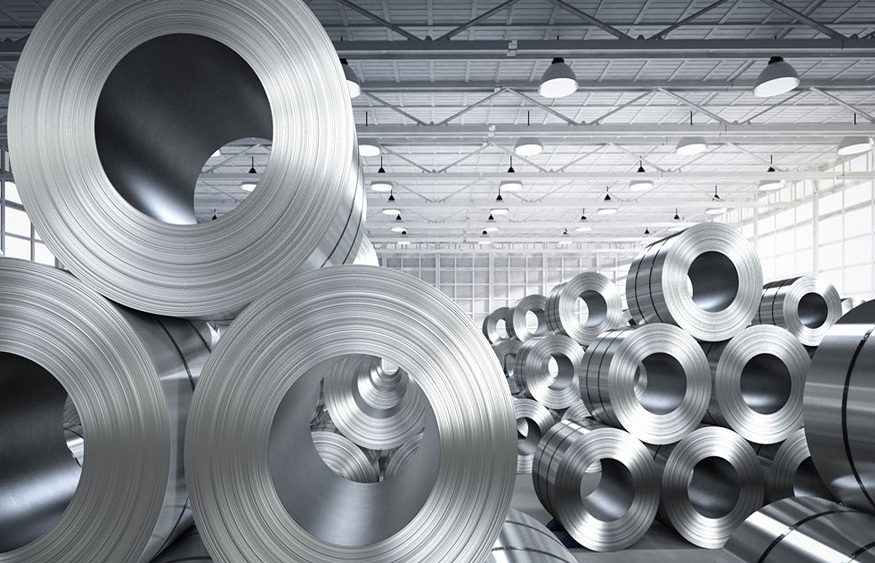

Sheet metal fabrication is essential in many sectors, including construction, automotive, electronics, and aerospace. It entails molding and manipulating flat metal sheets into desired shapes and structures. Sheet metal has the extraordinary capacity to be cautiously molded into a broad range of forms using a variety of processes. It develops into astonishing masterpieces that combine practicality with exquisite design when paired with modern production technologies. This blog will look at the common tools and techniques employed and their importance in modern production.

Understanding the Significances and Advantages

The fabrication process of metal sheets is important in modern production for various reasons:

- Versatility: Sheet metal may be manipulated into various sizes, shapes, and forms, making it an adaptable material for manufacturing various items and structures.

- Durability and strength: The metal sheets have great strength and durability, assuring the lifespan of produced components. This qualifies them for applications requiring tough materials.

- Cost-effectiveness: Sheet metal is frequently more cost-effective than other materials, such as solid metal blocks. It improves material utilization and lowers production costs.

- Efficiency: In the fabrication method of metal sheets, using advanced technology and automation leads to improved production efficiency and shorter lead times.

Tools Used in the Process of Fabrication

Sheet metal fabrication is the process of cutting, bending, shaping, and joining metal sheets using specialized equipment. Below are some commonly used tools:

- Shears: Used to shear huge sheets of metal into smaller pieces.

- Punches and Dies: Used to make holes or specified forms in metal.

- Press brakes: Used to precisely bend and shape metal sheets.

- Rollers: Used to mold flat sheets into cylindrical or curved forms.

- Welding Equipment: Allows metal sheets to be joined using welding procedures such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas).

Some Important Fabrication Techniques to Be Known

- Cutting: Sheets are cut into appropriate sizes and shapes using laser cutters, shears, and plasma cutters. The technique ensures precision and crisp edges.

- Bending: Metal sheets are bent at particular angles using press brakes. To produce correct results, this procedure necessitates meticulous measuring and placement.

- Forming: Metal sheets may be formed into cylindrical or curved shapes using rollers. This method may make pipes, tubes, or circular shapes.

- Joining: Welding, riveting or fastening with screws or adhesives are all techniques for joining metal sheets. Welding creates a strong and long-lasting connection, whereas riveting allows for more disassembly freedom.

- Finishing: Post fabrication, the metal surface may be polished, ground, or coated to improve aesthetics while safeguarding against corrosion.

Conclusion

Sheet metal fabrication is an important procedure that allows for the manufacturing of complicated and accurate metal components. Every stage, from cutting and bending to molding and assembling, necessitates precise craftsmanship and specialized instruments. Understanding the fundamentals of fabrication procedure helps grasp its importance and role in numerous sectors, leading to the production of new and functional products. Whether it’s the smooth curves of a vehicle body or the precision-engineered elements of a machine, the fabrication process plays an important role in shaping the world.